Introduction

In today’s rapidly evolving world, fire safety remains a paramount concern for industries of all types. The ability to swiftly and effectively address fire-related incidents can mean the difference between minimal damage and catastrophic losses. In the pursuit of becoming a superhero of improvisation in fire safety, organizations must rely on key performance indicators (KPIs) to measure and optimize their fire safety protocols. Four vital KPIs – MTTA, MTTR, MTBF, and MTTF – hold the key to achieving this status. In this article, we will explore these KPIs and their relevance in enhancing fire safety while providing industry-specific examples of assets and maintenance activities.

1) Mean Time to Acknowledge (MTTA)

MTTA, or Mean Time to Acknowledge, is a crucial KPI that measures the time taken from the occurrence of a potential fire hazard to the point at which it is formally recognized by the responsible personnel. Swift acknowledgment is vital as it allows for the initiation of fire safety protocols promptly. For example, in a manufacturing facility, an automated fire detection system equipped with advanced sensors can significantly reduce MTTA by immediately alerting the designated team to a potential fire outbreak.

2) Mean Time to Respond (MTTR)

MTTR, or Mean Time to Respond, gauges the average time required to respond to a fire incident from the moment it is acknowledged. A rapid response is instrumental in controlling the fire before it escalates and causes severe damage. To illustrate, consider an oil refinery that implements a well-structured emergency response plan with designated teams ready to address potential fire threats. By optimizing their response time through regular drills and training, the MTTR can be minimized, enabling quicker containment and mitigation of the fire.

3) Mean Time Between Failures (MTBF)

MTBF, or Mean Time Between Failures, is a critical KPI used to evaluate the reliability of fire safety equipment and systems. It measures the average time between two consecutive failures, providing valuable insights into the maintenance needs of crucial assets. For instance, a hotel’s fire suppression system, including fire alarms and sprinklers, requires regular inspections and maintenance. By monitoring MTBF data and scheduling preventive maintenance, the hotel can ensure that the fire safety systems are always in optimal working condition.

4) Mean Time to Failure (MTTF)

MTTF, or Mean Time to Failure, is a variant of MTBF but focuses on non-repairable assets. This KPI estimates the average time until an asset becomes unusable or fails beyond repair. For example, consider fire extinguishers used in a data center. Although fire extinguishers are non-repairable assets, tracking their MTTF allows data center operators to replace them proactively before their end of life, ensuring uninterrupted fire protection.

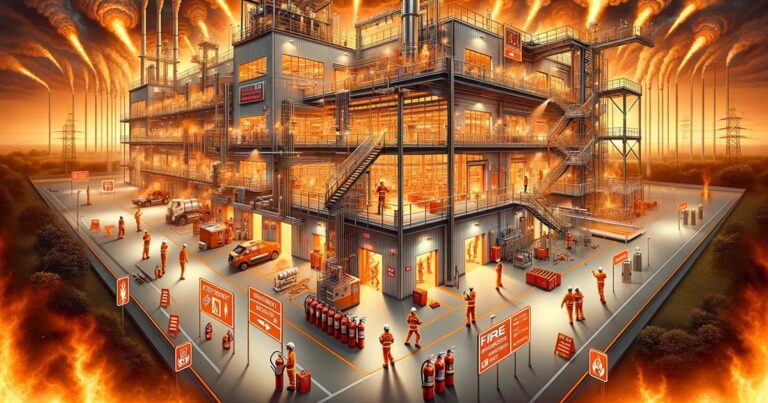

5) Industry-Specific Example: Power Plant

Let’s explore how these KPIs apply to a power plant, where fire safety is of utmost importance due to the presence of highly flammable materials and potential for catastrophic accidents.

MTTA:

In a power plant, early detection of fires is crucial. Implementing automated fire detection systems with advanced thermal cameras and smoke detectors can significantly reduce MTTA. Regular training and drills ensure that personnel are well-prepared to respond immediately upon acknowledgment.

MTTR:

In case of a fire, swift response is essential to prevent its spread. Having dedicated fire response teams equipped with appropriate firefighting equipment can minimize MTTR. Regular maintenance and testing of firefighting equipment guarantee their functionality during emergencies.

MTBF:

Power plants rely on various assets, such as generators and electrical systems, to function safely. Monitoring the MTBF of critical equipment helps identify potential failures, allowing maintenance teams to perform proactive inspections and minimize the risk of fire incidents.

MTTF:

Certain assets in power plants, like transformers, have a limited lifespan. Tracking their MTTF enables operators to replace aging transformers before they fail and cause hazardous situations.

Conclusion

Becoming a superhero of improvisation in fire safety demands a strategic focus on key performance indicators like MTTA, MTTR, MTBF, and MTTF. By efficiently measuring and optimizing these KPIs, industries can fortify their fire safety protocols and protect their assets, employees, and the surrounding environment. Investing in early detection, rapid response, proactive maintenance, and asset lifecycle management will ensure organizations are well-prepared to handle fire incidents effectively, becoming true champions of fire safety.