Introduction

In an increasingly competitive and cost-conscious environment, businesses across sectors are focusing on optimizing their operations. One significant area of focus is maintenance cost, a crucial metric that affects the financial health and operational efficiency of organizations. This article delves into what constitutes maintenance costs, their importance, and how they are managed in the Indian context, along with relevant data and insights to understand their impact comprehensively.

Understanding Maintenance Costs

Maintenance costs refer to the expenses incurred to keep equipment, buildings, and other assets in optimal working condition. These costs are essential for prolonging the life of assets, ensuring safety, and preventing costly breakdowns and disruptions. Maintenance expenses can be categorized into several types, including preventive, predictive, and corrective maintenance.

Preventive Maintenance

Preventive maintenance is performed regularly and is scheduled based on time or usage to prevent equipment failure before it actually occurs. For instance, industries such as manufacturing and aviation invest heavily in regular checks to ensure uninterrupted operations. In India, where the manufacturing sector contributes around 17-18% to the GDP, preventive maintenance plays a pivotal role in enhancing productivity and reducing downtime.

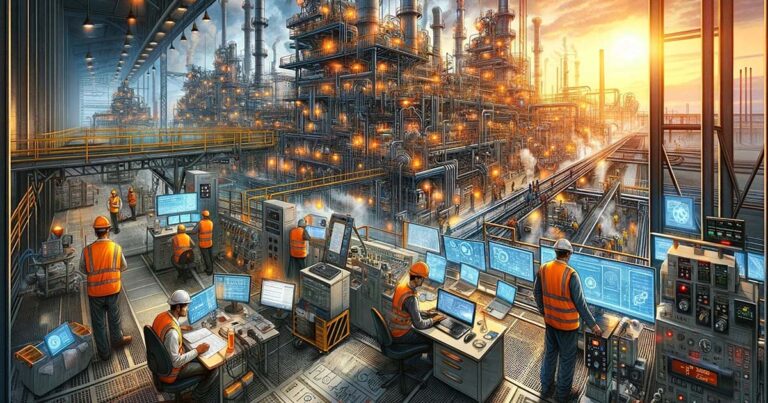

Predictive Maintenance

Leveraging data and technology to predict when maintenance should be performed, predictive maintenance allows businesses to take action before failures occur. This method relies on condition-monitoring equipment and advanced analytics. The advent of the Internet of Things (IoT) has significantly boosted the adoption of predictive maintenance in India, particularly in sectors like telecommunications and information technology.

Corrective Maintenance

Corrective maintenance occurs after a failure has been detected and is aimed at restoring an asset to its proper working condition. While this approach can be costlier than preventive methods, it is sometimes necessary when unexpected breakdowns occur.

The Impact of Maintenance Costs

Maintenance costs significantly impact an organization’s bottom line. According to a report by the Confederation of Indian Industry (CII), companies in India can spend between 15% and 40% of their operational budgets on maintenance activities, depending on the industry sector. For heavy industries like oil and gas or mining, the higher end of this range is more typical due to the complex and expensive machinery involved.

Reducing these costs without compromising on safety or efficiency requires strategic planning and investment in smart technologies. Businesses that effectively manage their maintenance costs can improve their competitive edge by reducing operational expenses and increasing asset reliability.

Strategies to Manage Maintenance Costs in India

Adoption of Technology

Indian companies are increasingly turning to technology solutions to streamline their maintenance processes. Digital tools such as Enterprise Asset Management (EAM) software, Computerized Maintenance Management Systems (CMMS), and Asset Performance Management (APM) platforms are becoming staples in industries aiming to reduce costs through efficient maintenance strategies.

Training and Skills Development

Investing in training for maintenance staff is another critical factor. Well-trained personnel can identify potential issues before they escalate into costly repairs or replacements. Continuous training and certification ensure that the maintenance team is updated with the latest technological advancements and best practices in asset management.

Outsourcing Maintenance

Outsourcing is a viable option for businesses looking to reduce their maintenance overheads. Specialized maintenance firms often have the expertise and equipment that individual companies may lack, providing a cost-effective solution without compromising the quality of maintenance.

Regulatory Compliance and Safety Standards

In India, adhering to regulatory compliance and safety standards is not just mandatory but also a crucial aspect of maintenance management. The Factory Act of 1948 and the Electricity Act of 2003 are just two examples of the legal framework within which Indian businesses operate, requiring them to maintain their equipment and facilities to specified standards.

The Future of Maintenance in India

As India continues to grow and modernize, the role of maintenance in business operations will evolve. The integration of artificial intelligence (AI) and machine learning (ML) in maintenance systems is poised to transform how businesses approach their maintenance strategies. These technologies not only predict potential failures but also prescribe preventative measures, thereby reducing downtime and extending the life of the equipment.

Conclusion

In conclusion, understanding and effectively managing maintenance costs is vital for the sustainability and success of any business. In the dynamic economic landscape of India, where cost-efficiency paired with innovation is the key to competitiveness, maintenance management demands a strategic approach backed by technology and foresight. This focus not only ensures operational efficiency but also aligns with the broader goals of sustainability and safety, essential for long-term business viability.