Introduction:

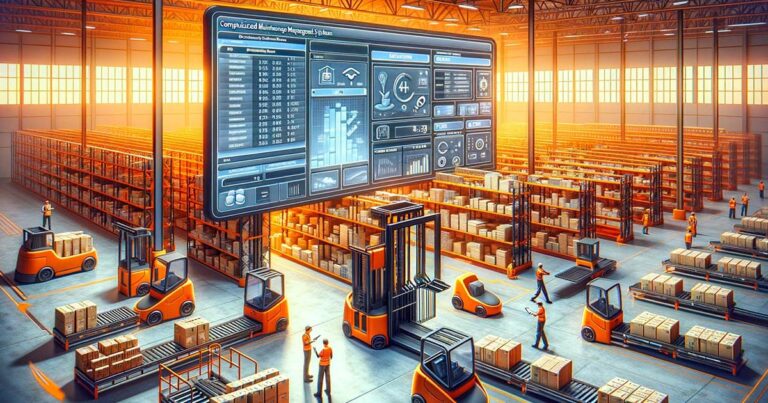

The maintenance of equipment and facilities is an essential aspect of any business, and it becomes more critical in industries where downtime can lead to catastrophic consequences. To manage maintenance effectively, a team must be in place to identify, prioritize and solve problems. However, managing maintenance can be complicated, and without proper tools, it can become challenging to keep track of everything. This is where Computerized Maintenance Management Systems (CMMS) come into play. In this blog, we will explore the role of CMMS in reliability team management and why it’s crucial to know about it.

The Role of CMMS in Reliability Team Management:

CMMS is a software solution designed to help maintenance teams manage their assets effectively. It provides a centralized platform to track work orders, preventive maintenance schedules, asset history, inventory management, and more. CMMS helps in maintaining accurate records of the maintenance activities, providing an insight into the assets’ condition, and helps prioritize maintenance tasks, improving the overall reliability of equipment.

One of the critical aspects of reliability team management is to identify potential problems and address them before they lead to significant downtime. A CMMS can help achieve this goal by providing a systematic approach to maintenance. With the help of preventive maintenance schedules, reliability teams can stay on top of the maintenance requirements and identify potential issues. Additionally, a CMMS can help manage work orders effectively by tracking the progress of maintenance activities, providing real-time information, and reducing the time required to complete a task.

Why You Need to Know About CMMS in Reliability Team Management:

In India, several industries, such as oil and gas, power generation, and manufacturing, heavily rely on machinery and equipment. Any unplanned downtime in these industries can lead to significant financial losses, affecting the overall productivity of the company. Reliability team management plays a crucial role in minimizing these losses by identifying potential problems and addressing them before they become a significant issue. A CMMS can help reliability teams achieve this goal by providing a centralized platform to manage maintenance activities, reducing downtime, and increasing asset reliability.

According to a report by MarketsandMarkets, the CMMS market in India is expected to grow from USD 198 million in 2020 to USD 410 million by 2025, with a CAGR of 15.6% during the forecast period. This growth is driven by the increasing demand for efficient asset management solutions, growing awareness about predictive maintenance, and the need to reduce maintenance costs.

In addition to the financial benefits, implementing a CMMS can also improve safety, compliance, and regulatory requirements. A CMMS can help in maintaining an accurate record of maintenance activities, which is essential for safety and regulatory audits. It can also help in managing inventory effectively, reducing the risk of accidents due to faulty equipment.

Conclusion:

In conclusion, the role of CMMS in reliability team management cannot be overstated. It provides a centralized platform to manage maintenance activities, reducing downtime, and increasing asset reliability. In India, where industries heavily rely on machinery and equipment, implementing a CMMS can help minimize financial losses, improve safety, compliance, and regulatory requirements. With the growing demand for efficient asset management solutions, it’s crucial to know about CMMS and its benefits in reliability team management.