Introduction

In the dynamic world of the chemical industry, innovation and efficiency play a pivotal role in ensuring sustained growth and competitiveness. As India emerges as a global player in chemical manufacturing, companies are exploring cutting-edge technologies to streamline operations and improve productivity. One such transformative approach is Autonomous Maintenance (AM), which has proven to be a game-changer for the Indian chemical sector. In this blog, we will delve into the significance of Autonomous Maintenance, its implementation, and the far-reaching impact it has on the chemical industry in the Indian context.

1) The Foundation of Autonomous Maintenance

Autonomous Maintenance, a pillar of Total Productive Maintenance (TPM), empowers frontline operators to take greater responsibility for the upkeep of their equipment. In the Indian chemical industry, where operational downtime can be costly, AM aims to eliminate unscheduled breakdowns, reduce maintenance costs, and enhance overall equipment effectiveness (OEE).

2) Bridging the Skills Gap

In the Indian chemical sector, finding skilled maintenance personnel has been a challenge. By implementing AM, companies can bridge the skills gap by upskilling their operators. Through structured training programs, operators acquire the necessary technical knowledge and problem-solving skills, enabling them to handle routine maintenance tasks efficiently. As a result, the reliance on specialized maintenance teams decreases, leading to significant cost savings.

3) Data-Driven Decision Making

Incorporating AM in the chemical industry allows for the collection and analysis of real-time equipment data. Through the deployment of sensors and IoT-enabled devices, operators gain insights into equipment health, performance, and anomalies. This data-driven approach enables predictive maintenance, reducing the chances of unexpected failures and optimizing maintenance schedules. Indian chemical companies can thus enhance their competitiveness by maximizing uptime and minimizing downtime.

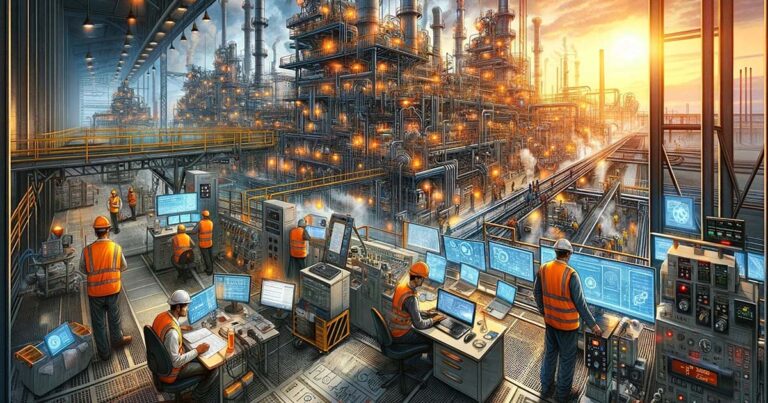

4) Enhancing Safety and Compliance

Safety is paramount in the chemical industry. By engaging operators in the maintenance process, AM fosters a culture of ownership and accountability. Operators become more attuned to potential safety hazards and are proactive in addressing them. Furthermore, regular maintenance checks ensure equipment compliance with industry standards and regulations, minimizing the risk of accidents and environmental incidents.

5) Improving Overall Equipment Effectiveness (OEE)

In the context of the Indian chemical industry, optimizing OEE is critical for achieving higher productivity. AM focuses on the prevention of equipment deterioration and the early detection of defects, contributing to improved availability, performance, and quality. As a result, companies witness a substantial increase in their overall equipment efficiency, positively impacting their bottom line.

6) Case Studies and Success Stories

Several chemical companies in India have embraced AM with remarkable results. One such success story is that of a leading fertilizer manufacturer in Gujarat. By empowering their operators through AM, the company reduced maintenance costs by 30%, increased equipment availability by 20%, and witnessed a 15% rise in productivity within the first year of implementation.

7) Overcoming Challenges in Implementation

While the benefits of Autonomous Maintenance are evident, implementing AM in the chemical industry comes with its own set of challenges. Resistance to change, lack of initial operator engagement, and the need for significant upfront investments in technology and training are common hurdles faced by companies. However, with proper planning, strong leadership support, and a clear roadmap, these obstacles can be overcome.

Conclusion

The Indian chemical industry is at a crossroads of technological advancement, and Autonomous Maintenance emerges as a beacon of progress. By empowering frontline operators, embracing data-driven decision-making, and fostering a culture of safety and ownership, chemical companies can enhance productivity, reduce downtime, and ensure sustained growth in an increasingly competitive market. The success stories of early adopters of AM in India demonstrate the transformative potential of this approach, and as more companies realize its benefits, the future of the Indian chemical industry looks brighter than ever.