Introduction

In today’s technologically advanced world, electrical systems play a vital role in powering industries, businesses, and homes. The smooth functioning of these systems is crucial for uninterrupted operations and the overall safety of individuals. One effective tool that has revolutionized electrical maintenance practices is a Computerized Maintenance Management System (CMMS). In this blog, we will explore the numerous benefits that a CMMS offers in the context of electrical maintenance, specifically focusing on its significance in the Indian landscape.

Enhanced Asset Management:

Managing electrical assets can be a complex task, particularly when dealing with large-scale facilities. A CMMS provides a comprehensive solution for efficient asset management. It allows maintenance teams to track and organize critical information such as equipment specifications, maintenance history, warranties, and documentation. With the ability to store and retrieve data, a CMMS simplifies asset tracking and minimizes the risk of equipment failure.

In the Indian context, where power outages and electrical system failures are not uncommon, a CMMS can assist in identifying weak links in the infrastructure, enabling proactive maintenance and reducing downtime.

Streamlined Preventive Maintenance:

Preventive maintenance is a key aspect of electrical maintenance to prevent costly breakdowns and ensure the optimal performance of electrical systems. A CMMS facilitates the scheduling and tracking of preventive maintenance tasks, such as equipment inspections, calibrations, and component replacements. By automating maintenance schedules, technicians can stay ahead of potential issues, leading to increased system reliability and longevity.

In India, where electrical maintenance often faces resource constraints, a CMMS can help prioritize preventive maintenance activities and allocate resources effectively, leading to improved system efficiency.

Efficient Work Order Management:

Effective work order management is essential for ensuring timely and accurate execution of maintenance tasks. A CMMS enables streamlined work order generation, assignment, and tracking. Maintenance personnel can access work orders through mobile devices, reducing paperwork and enhancing communication across the team.

In the Indian context, where large facilities are spread across vast areas, a CMMS can provide real-time updates and facilitate coordination among technicians, ensuring faster response times and minimizing service disruptions.

Inventory Control and Procurement:

Maintaining an optimal inventory of electrical spare parts is crucial to avoid delays in repair and maintenance activities. A CMMS assists in managing inventory levels by tracking stock levels, generating alerts for reordering, and recording material consumption. By having better control over inventory, organizations can minimize downtime caused by unavailability of essential components.

In India, where power grids span diverse geographical regions, a CMMS can assist in managing spare parts across multiple locations, reducing procurement lead times and improving overall maintenance efficiency.

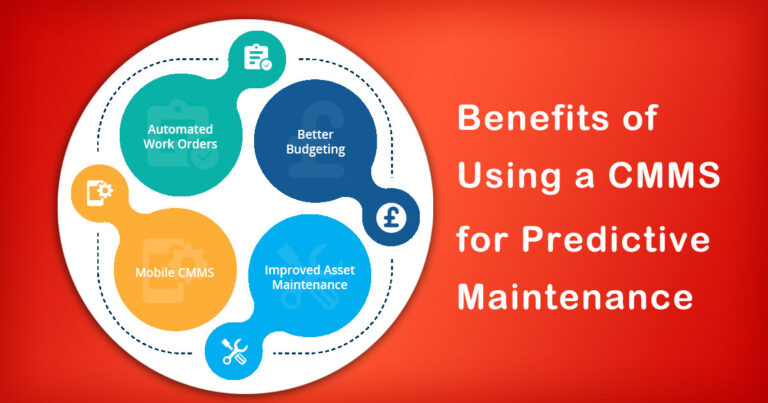

Data-Driven Decision Making:

One of the most significant advantages of using a CMMS is the availability of data for analysis and decision making. A CMMS captures maintenance-related data, including equipment performance, failure rates, and maintenance costs. By analyzing this data, organizations can identify trends, predict failures, and make informed decisions to optimize maintenance strategies.

In the Indian context, where power consumption is growing rapidly, analyzing maintenance data using a CMMS can aid in identifying energy-saving opportunities and optimizing electrical system performance.

Conclusion:

As the demand for reliable electrical systems continues to grow, the need for efficient maintenance practices becomes paramount. A CMMS offers numerous benefits for electrical maintenance in the Indian context. By streamlining asset management, enabling preventive maintenance, improving work order management, enhancing inventory control, and facilitating data-driven decision making, a CMMS can significantly improve the reliability and efficiency of electrical systems. Embracing this technology can lead to reduced downtime, enhanced safety, and cost savings in electrical maintenance operations across the country.

Incorporating a CMMS in electrical maintenance practices is a step towards a more sustainable and reliable power infrastructure in India.