Best Practices for Managing Maintenance Training

Unlock Maintenance Training Success: Best Practices for Skill Development, Ongoing Learning, and Effective Measurement.

Unlock Maintenance Training Success: Best Practices for Skill Development, Ongoing Learning, and Effective Measurement.

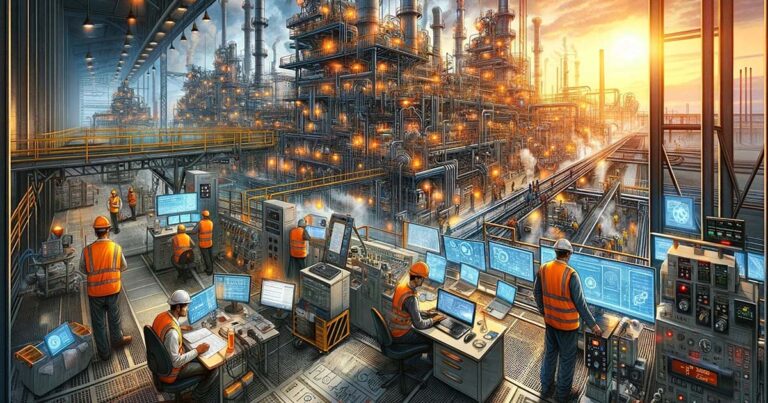

Maintenance is an essential part of any organization to ensure that the equipment and infrastructure remain functional and efficient. However, maintenance tasks can quickly pile up, leading to a maintenance backlog that can be overwhelming to manage. In this blog, we will discuss the best practices for managing maintenance backlogs in an Indian context. It…

Equipment downtime is a critical challenge faced by many manufacturing companies, particularly in India, where equipment failure is a common occurrence. In a manufacturing setting, equipment downtime can lead to significant losses, ranging from decreased productivity and increased operating costs to missed delivery deadlines and decreased customer satisfaction. Therefore, it’s essential for companies to manage…

Reliability centered maintenance (RCM) is a proactive maintenance strategy that focuses on identifying and addressing potential equipment failures before they occur. RCM aims to improve the reliability, safety, and performance of equipment while minimizing maintenance costs. In an Indian context, RCM can play a significant role in optimizing maintenance and minimizing downtime, thus contributing to…