Introduction

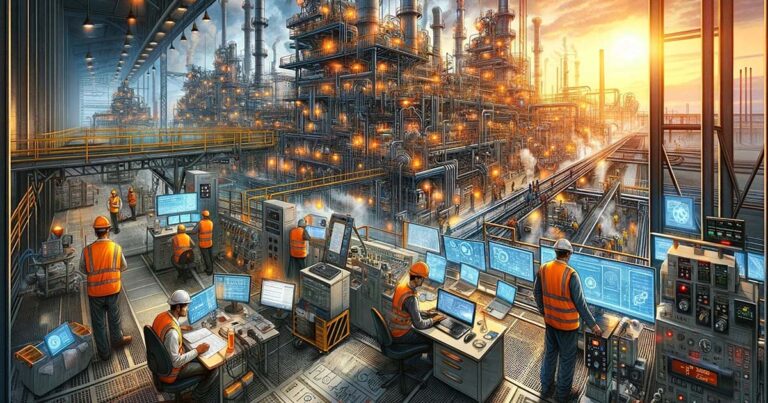

Maintenance is an essential aspect of any industrial or commercial activity, ensuring that equipment is functioning correctly and efficiently. However, poor maintenance can result in losses in productivity, revenue, and even safety concerns. In this blog, we will explore the losses caused due to poor maintenance in an Indian context, backed by research and facts.

Impact of Poor Maintenance

The consequences of inadequate maintenance can be dire, and the losses can be enormous. In India, the Indian Society of Heating, Refrigerating and Air Conditioning Engineers (ISHRAE) estimated that the country loses over $12 billion annually due to inadequate maintenance of HVAC (Heating, Ventilation, and Air Conditioning) systems. Furthermore, the Indian Society of Heating, Refrigeration and Air Conditioning Engineers reported that the cost of maintenance of HVAC systems in India is approximately 20-30% of the equipment’s initial cost. However, many companies overlook the importance of regular maintenance to cut down on expenses.

Loss of Productivity

Poorly maintained equipment can result in unexpected breakdowns, which can lead to production delays and downtime. For instance, in a manufacturing plant, a sudden machine breakdown can halt the production line, leading to a backlog of orders and delayed deliveries. In India, a study conducted by Frost & Sullivan revealed that unplanned downtime in the manufacturing sector costs approximately $20 billion per annum. It is important to note that the loss of productivity due to unexpected equipment breakdowns is preventable through scheduled maintenance.

Decrease in Equipment Lifespan

Neglecting regular maintenance of equipment can lead to premature failure, resulting in the need for replacement or repair. The cost of replacing machinery can be incredibly high, resulting in significant losses for the company. In addition, the cost of repairing equipment that has failed due to inadequate maintenance can be substantial, and the length of downtime required to repair the equipment can negatively impact production. In India, the cost of equipment replacement can range from 50% to 100% of the original cost.

Safety Concerns

The risks associated with poorly maintained equipment are not limited to productivity and financial losses. Equipment that is not maintained can pose safety hazards to workers, resulting in accidents or injuries. For instance, in 2019, a boiler exploded in a factory in Uttar Pradesh, killing at least 25 people and injuring several others. The incident was attributed to inadequate maintenance of the equipment. Therefore, it is crucial to maintain equipment to ensure the safety of employees.

Environmental Impact

Poorly maintained equipment can also lead to environmental consequences. For instance, a poorly maintained HVAC system can lead to a buildup of pollutants and allergens, impacting indoor air quality. Additionally, neglected equipment can consume more energy than required, resulting in increased energy consumption and higher carbon emissions. India is the third-largest emitter of carbon dioxide globally, and the inefficient use of energy due to poor maintenance of equipment is a significant contributor to this issue.

Preventive Maintenance

Preventive maintenance is a proactive approach to equipment maintenance, aimed at preventing equipment breakdowns and prolonging equipment lifespan. Preventive maintenance involves regular inspections, cleaning, lubrication, and repair of equipment to keep them in good working condition. Implementing preventive maintenance practices can significantly reduce the losses caused by inadequate maintenance.

Conclusion

In conclusion, the impact of poor maintenance can be catastrophic, resulting in loss of productivity, equipment lifespan, safety hazards, and environmental consequences. In India, the losses caused by inadequate maintenance are estimated to be significant, amounting to billions of dollars annually. However, companies can prevent these losses by implementing preventive maintenance practices, including regular inspections, cleaning, and repair of equipment. It is essential for companies to prioritize maintenance to ensure smooth operations, safety, and sustainability.