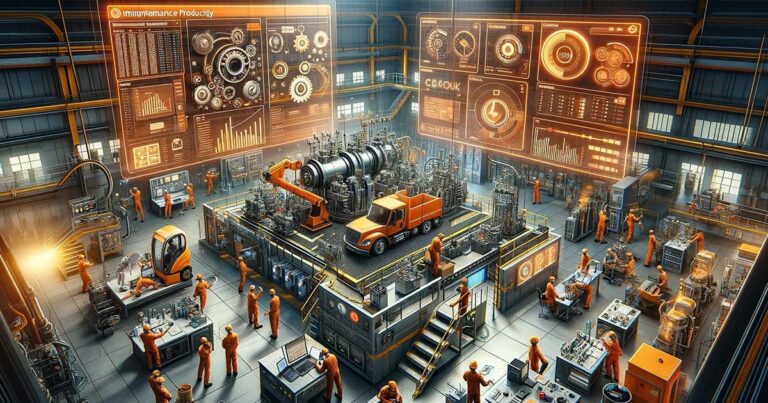

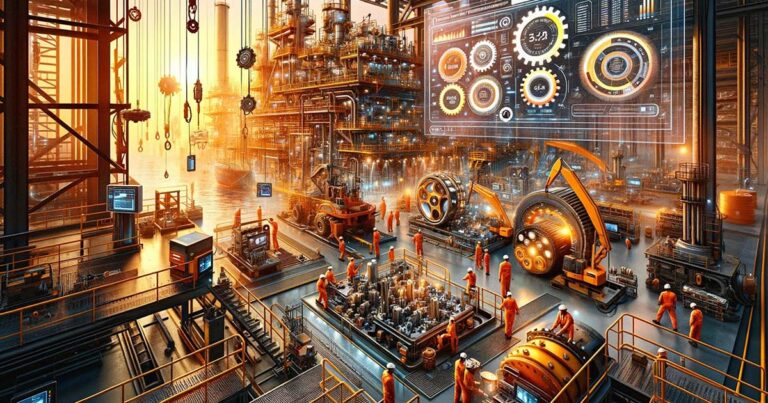

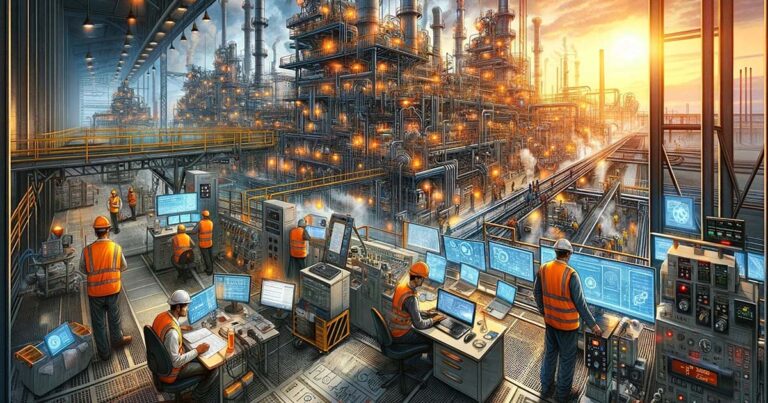

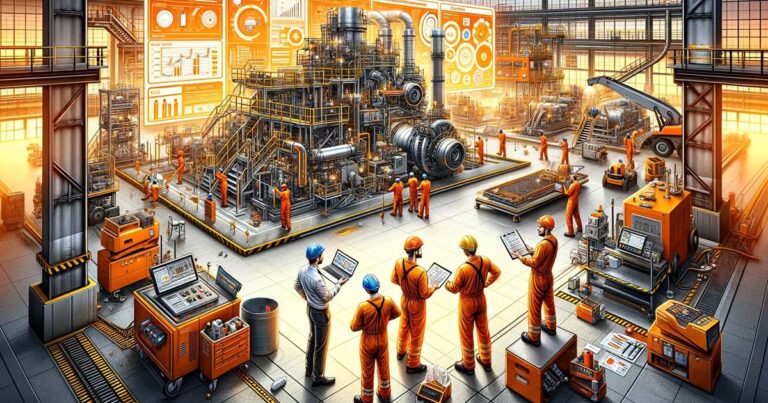

How to Improve Maintenance Productivity

Introduction In India, maintenance plays a critical role in ensuring that machines, equipment, and facilities are always in good working condition. In many industries, maintenance teams often face challenges in meeting production targets and keeping downtime to a minimum. As a result, improving maintenance productivity has become a critical need in today’s competitive business environment….