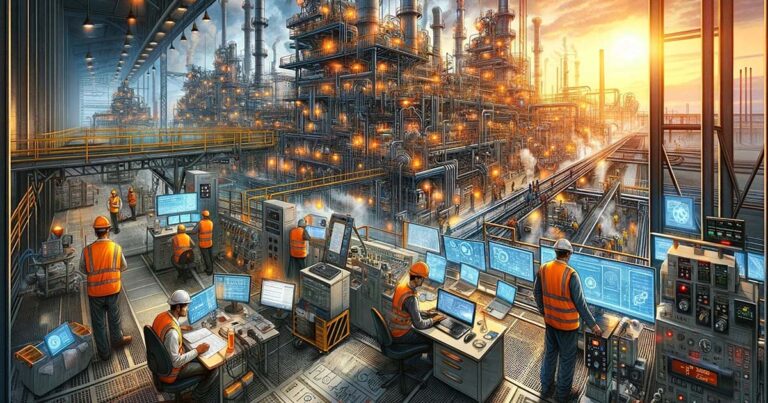

The Role of CMMS in Quality Control

The manufacturing sector is one of the most crucial sectors in the Indian economy, contributing significantly to the country’s growth. The manufacturing sector has witnessed massive technological advancements over the years, and computerized maintenance management systems (CMMS) have become a crucial tool for ensuring quality control. In this blog, we will discuss the role of…