Introduction

In recent years, the Indian oil and gas industry has experienced significant transformations driven by technological advancements. Among these innovations, autonomous maintenance stands out as a game-changer, revolutionizing the way operations are managed and maintained in this critical sector. This blog explores the role of autonomous maintenance in India’s oil and gas industry, shedding light on its benefits, challenges, and the potential it holds for a sustainable future.

The Emergence of Autonomous Maintenance:

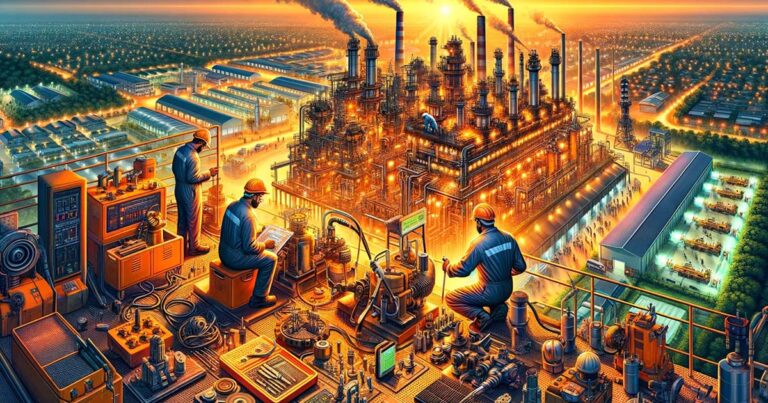

Autonomous maintenance, as a concept, originated from the Total Productive Maintenance (TPM) philosophy, aiming to empower front-line workers to take ownership of their equipment’s well-being. In the oil and gas industry, where large and complex machinery is the backbone of operations, the adoption of autonomous maintenance has been a gradual yet transformative process.

Enhanced Safety and Reliability:

Safety is a paramount concern in the oil and gas sector, and autonomous maintenance has proven to be a boon in this regard. With automated monitoring and self-diagnostic capabilities, equipment can detect and report abnormalities, reducing the risk of catastrophic failures and ensuring proactive maintenance. This results in fewer accidents, minimized downtime, and ultimately, enhanced reliability of operations.

Increased Operational Efficiency:

The vast infrastructure of the oil and gas industry requires meticulous maintenance to maximize productivity. Autonomous maintenance streamlines the process by optimizing maintenance schedules, reducing manual inspections, and eliminating unnecessary downtime. As a result, the industry experiences increased operational efficiency, leading to cost savings and improved profitability.

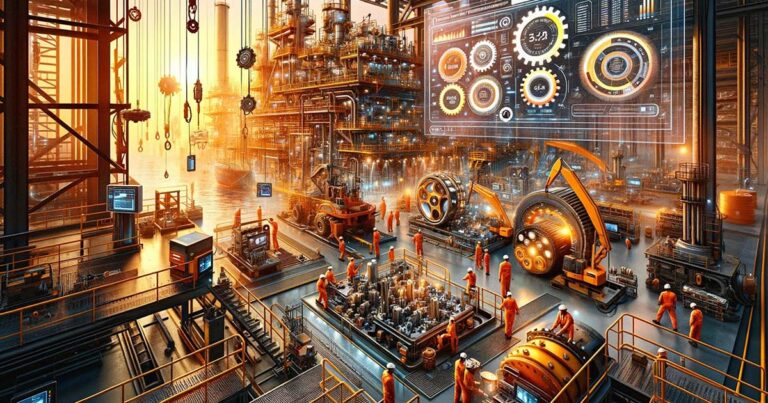

Remote Monitoring and Predictive Analytics:

One of the most significant advantages of autonomous maintenance is the ability to remotely monitor equipment health and performance. In a country as geographically diverse as India, where oil and gas installations can be situated in challenging terrains, remote monitoring saves time and resources. Additionally, predictive analytics tools allow operators to forecast potential failures, plan maintenance activities more effectively, and prevent unplanned shutdowns.

Skill Development and Workforce Empowerment:

Implementing autonomous maintenance necessitates upskilling the workforce to handle the new technologies and tools effectively. This process creates opportunities for skill development, empowering workers with valuable expertise in operating and maintaining advanced systems. As a result, this leads to a more competent and confident workforce that is better equipped to tackle complex challenges.

Environmental Impact:

The oil and gas industry is under increasing scrutiny for its environmental impact. Autonomous maintenance contributes to sustainability efforts by optimizing energy consumption, reducing emissions, and minimizing oil spills through timely interventions. By adopting environmentally conscious practices, the industry can align itself with India’s commitment to combating climate change.

Challenges and Considerations:

While the potential benefits of autonomous maintenance in the oil and gas industry are vast, several challenges must be addressed to ensure successful implementation:

Initial Investment:

Integrating autonomous systems requires significant upfront investment, which might deter some companies from embracing the technology.

Data Security:

Remote monitoring and connected systems raise concerns about data security and privacy. Robust cybersecurity measures are crucial to safeguard sensitive information.

Workforce Acceptance:

The introduction of autonomous maintenance might be met with resistance from the existing workforce. Proper training and communication are essential to gain their acceptance and cooperation.

Conclusion:

Autonomous maintenance is a transformative force in India’s oil and gas industry, redefining how operations are managed and maintained. By embracing this cutting-edge technology, companies can enhance safety, boost operational efficiency, and contribute to a more sustainable future. As the nation’s demand for energy continues to grow, the role of autonomous maintenance will be pivotal in driving the industry towards a safer, more reliable, and environmentally conscious path. Embracing the challenges and capitalizing on the benefits of autonomous maintenance is the key to a thriving oil and gas sector in India.