Introduction

The dairy industry plays a crucial role in the Indian economy, contributing significantly to employment generation and the nation’s GDP. With the growing demand for dairy products, it has become essential for dairy manufacturers to adopt modern technologies and management systems to streamline their operations and enhance productivity. One such system that has revolutionized the dairy industry is the Computerized Maintenance Management System (CMMS). In this article, we will delve into the importance of CMMS in the Indian dairy industry, exploring its benefits, challenges, and implementation strategies.

1. Streamlining Maintenance Processes

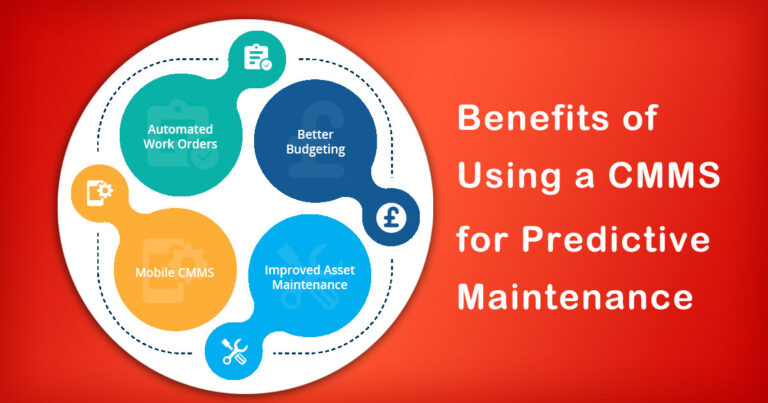

Maintenance is a critical aspect of the dairy industry, as it directly affects the quality and safety of dairy products. CMMS offers a comprehensive solution for managing maintenance activities, enabling dairy manufacturers to streamline their processes effectively. By automating maintenance schedules, tracking equipment performance, and managing work orders, CMMS helps prevent breakdowns and minimize production downtime. This proactive approach to maintenance ensures that the dairy plants operate at optimum levels, reducing maintenance costs and increasing overall efficiency.

2. Ensuring Compliance with Quality Standards

The Indian dairy industry is governed by stringent quality standards set by regulatory bodies such as the Food Safety and Standards Authority of India (FSSAI). Compliance with these standards is crucial to maintain consumer trust and ensure food safety. CMMS plays a vital role in this regard by facilitating adherence to quality standards. It helps dairy manufacturers keep track of equipment calibration, cleaning, and maintenance records, ensuring that all necessary activities are performed as per the prescribed guidelines. By maintaining an accurate record of maintenance activities, CMMS aids in demonstrating compliance during audits and inspections.

3. Inventory Management and Spare Parts Optimization

Efficient inventory management is crucial for the smooth functioning of any industry, and the dairy sector is no exception. CMMS provides a centralized platform to manage spare parts and inventory, eliminating the need for manual tracking and reducing the chances of stockouts or overstocking. By maintaining a real-time inventory database, CMMS enables dairy manufacturers to optimize their spare parts procurement, minimize costs, and ensure timely availability of critical components. This not only improves operational efficiency but also minimizes downtime caused by equipment failure due to unavailable spare parts.

4. Data-Driven Decision Making

CMMS collects and analyzes vast amounts of data related to equipment performance, maintenance history, and downtime. This data can be leveraged to gain valuable insights into the dairy manufacturing processes. By generating reports and analytics, CMMS empowers dairy managers to make informed decisions regarding maintenance strategies, equipment replacement, and resource allocation. The ability to identify patterns and trends in equipment performance enables proactive maintenance planning, reducing the likelihood of sudden breakdowns and improving overall equipment reliability.

5. Implementation Challenges and Strategies

While CMMS offers significant benefits to the dairy industry, its successful implementation can be challenging. Lack of awareness, resistance to change, and inadequate training can hinder the adoption of CMMS. To overcome these challenges, dairy manufacturers need to emphasize the importance of CMMS among their workforce, provide comprehensive training, and ensure the availability of technical support. Additionally, collaboration with CMMS vendors and consultants can assist in smooth implementation, customization of the system, and continuous improvement.

Conclusion

The Indian dairy industry is experiencing remarkable growth, and to remain competitive, dairy manufacturers must embrace technological advancements. CMMS has emerged as a game-changer in the industry, enabling streamlined maintenance processes, ensuring compliance with quality standards, optimizing inventory management, and facilitating data-driven decision making. By implementing CMMS effectively, dairy manufacturers can enhance productivity, minimize downtime, and strengthen their position in the market. Embracing CMMS is not just a choice; it is a necessity for the sustainable growth of the Indian dairy industry.